企業理念 Corporate Philosophy

資源の再生利用 Recycling of resources

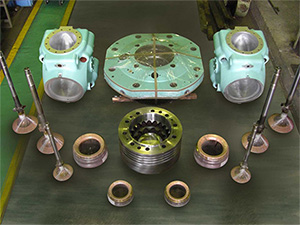

資源に乏しい我が国で貴重な資源が浪費されていることへの憂慮と反省から、昭和10年創始者である東剛生が「資源の再生利用」を理念の柱に、当時の公共交通機関であった木炭バスのエンジン再生修理及び鈑金プレス加工から事業を始めました。その後に起こる大戦を乗り越え、終戦後には水処理装置機器の研究に着手し、後に製品製作を始め、生命の源でもある水の再生にも力を注ぎ始めました。さらに同時期には、日本に於いて初めて低温溶接法が紹介されたのを受け、技術開発の一端として逸早く技術導入することで鋳鉄製品に対する溶接技術を開発し、それまで技術的に容易ではなかったその再生修理を可能といたしました。また、ディーゼル機関のピストン・バルブ等の特殊溶接法を技術開発し、それにより資源の再生利用を実践してまいりました。

Out of concern and regret that precious resources had been wasted in resource-poor Japan, Takeo Azuma, the founder of Azuma Kako, began business in 1935 by conducting repair and restoration of the engines and sheet metal presses for charcoal-powered buses, which were the public transportation of the time, with the motto “recycling of resources” as a pillar of the company’s philosophy. Overcoming the World War that subsequently occurred, we initiated a study of water processing devices in the postwar years and then started manufacturing products, pouring our energy into the recycling of water, the source of life. Furthermore, around the same period, in response to the introduction of the low-temperature welding method to Japan, he promptly introduced its technology as part of his technical development in order to develop the welding technique for cast-iron products, thus making possible the reconditioning and repair of those products, which had not been technically easy. We also developed a special welding method for pistons, valves, etc., in diesel engines, and We practiced the recycling of resources by using that method.

その後も積極的な技術開発・修得の精神を持ち、国内外の主要企業との提携により"溶射技術""金型補修技術""メッキ加工技術""プロペラ補修技術" "ホーニング・平面研磨技術""燃料弁補修技術"等、数多くの技術を収得し再生修理品種の拡充に努め、幅広いサービスをクライアントに提供させていただくと共に、より高度な技術、高品質な製品を求める業界のニーズに応えられるよう多面に於いて努力してまいりました。これに伴い舶用機器部品に関しましては、日本海事協会(NK)・ロイド船級協会(LR)・アメリカ船級協会(ABS)・ビューローベリタス(BV)・デットノルスケベリタス(DNV)他、各船級の認定を受け、また数多くのメーカーより修理補修の協力・認定工場として承認・認可され、「技術のアヅマ」として信頼していただけるブランドを確立してまいりました。

Even after that, with an enterprising spirit in developing and acquiring technologies, we acquired various techniques including “thermal spraying techniques,” “mold repair techniques,” “plating techniques,” “propeller repair techniques,” “honing/flat surface polishing techniques” and “fuel valve repair techniques” through cooperation with major companies at home and abroad, made efforts to expand the scope of parts to be reconditioned and repaired, and provided a wide variety of services to our clients. We also made efforts in various fields to satisfy the demands from industry seeking advanced technologies and high-quality products. Along with these efforts, the company has been certified for various class societies by Nippon Kaiji Kyokai (NK), Lloyd's Register of Shipping (LR), the American Bureau of Shipping (ABS), Bureau Veritas (BV), Det Norske Veritas (DNV) and others, and it has been approved and certified as a cooperative/certified repair works by many manufacturers. Thus, the company has established its brand as “Technological Azuma.”

日本国内に留まらず、台湾よりスタートし海外へのネットワークを広げて早30年。未だ見ぬ「未来」への歩みに貢献するため、関係各業界に留まらず、「資源の再生利用」の理念をもって、「改善・向上」の「心」と「技術」を忘れず、さらなる飛躍を目指し引き続き努力したく考えております。

Thirty years have already passed since the company spread its network beyond Japan to Taiwan and other countries. In order to make contributions to the steps toward the “future” we have yet to witness, we will strive, in the concerned fields as well as new fields, to make further leaps with the philosophy of “recycling resources,” while at the same time maintaining the “mind” and “techniques” for “improvement and enhancement”.

![]()

東化工へのお問い合わせは、メールフォームより受け付けております。