メンテナンス事業 Maintenance business

船舶用内燃機関 Engine components for vessels

船舶用エンジン部品のメンテナンスを行っています。

We conduct maintenance of engines for vessels.

陸上関連動力機器 Parts for land field

必要に応じたメンテナンスを行っております。

We conduct maintenance on an as-needed basis.

メンテナンスとは What is maintenance?

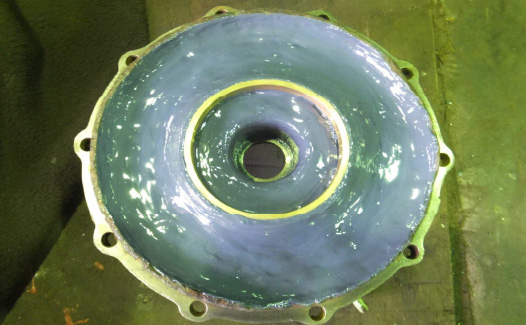

エンジン部品の中でも特に燃焼室の構成部品(ピストン冠、排気弁、シリンダカバー)は運転中に常時高温・腐食性燃焼ガスに晒される過酷な使用環境下で使用される為に焼損・ガス吹抜けが発生し、また燃料弁・燃料ポンプは摩耗に因り本来要求される性能が維持出来なくなり、放っておけば重大故障や燃費悪化などエンジンの正常な運転を妨げる要因となります。

弊社では定期整備時に故障・損耗が確認されたエンジン部品を豊富な経験・知識と確立された技術力を基にエンジンメーカーの品質管理・修理要領書に従い、新品を購入するよりも低価格、短納期で溶接・再生修理を行い、また交換を要する部品はメーカー純正部品を使用して整備を行いお客様のエンジンの正常運転をサポートしています。

Among engine parts, the constituting parts of the combustion chamber (piston crown, exhaust valve, cylinder cover) in particular are used under severe conditions where they are always exposed to high temperatures and corrosive combustion gas during operation, and therefore defects such as burning and gas blow are likely to occur. In addition, the fuel valve and fuel pump become unable to maintain their required performance due to wear, and if they are left untouched, severe accidents or worsening of fuel consumption may prevent normal engine operation.

We conduct welding and reconditioning/repair of such engine parts that are confirmed to have a fault or damage during periodical servicing based on our abundant experience and knowledge as well as established technical capabilities, while following the quality control and repair procedures provided by the engine manufacturer, at a lower price and with a shorter delivery time than those required for purchasing new parts. We also conduct the maintenance of parts requiring replacement by using the manufacturer’s genuine replacement parts so as to support the normal operation of the customer’s engine.

![]()

東化工へのお問い合わせは、メールフォームより受け付けております。